Construction Process

Custom Fly Rod

Construction Process

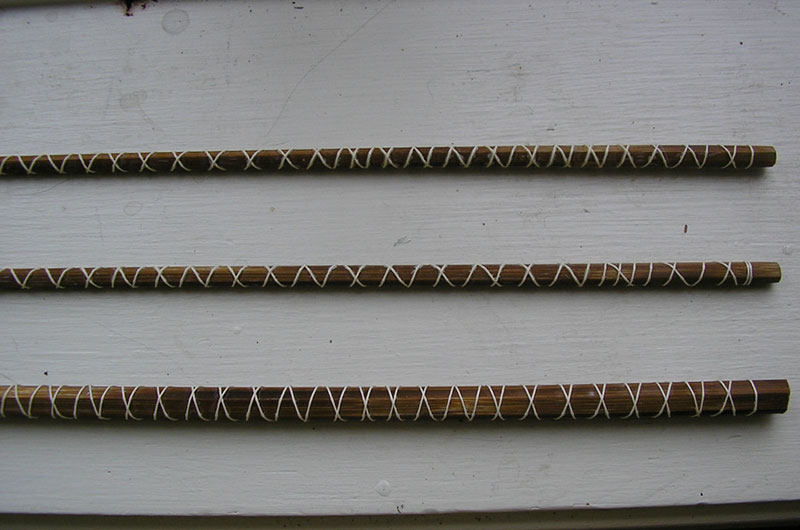

If you're looking for a new cane rod chances are you have a pretty good idea about what goes into making one. I start with quality cane from Andy Royer (The Bamboo Broker) and select a culm with dense power fibers. After filing the nodes, the culm is flamed, split and re-split. Strips are straightened, nodes pressed and dressed, and beveled to 60 degress. Hand planing is a slow and steady process, done over several days. The sections are glued and bound, and allowed to dry for several days. I use Titebond III to glue up rod sections. Once dry, the sections are lightly sanded and straightened. The finish work will take an additional 20 hours or so, and the final product will have three coats of spar urethane varnish polished to a semi-gloss finish for less glare on the water. The total process takes about 50 hours.

Currently I am only making flamed rods

Ready to order your custom fly rod ?

To order, simply send an email describing what you want. My email address is whcritch@comcast.net. I will send a reply. We can talk on the phone and finalize the details. If you're satisifed with the design parameters, your order will go on our board for completion. We require a 50% deposit with all orders and the balance + shipping cost (usually $15 in the U.S.) when the rod is ready to ship. THE CURRENT LEAD TIME FOR NEW RODS IS 120 DAYS AFTER RECEIPT OF DEPOSIT.

We do not use credit cards. You can pay by check or money order or through Paypal.